Chem Arrow announces the launch of FinCoater, a lubricant applicator that can reduce usage up to 50%!

FinCoater gives fin press operators exceptional application control. The FinCoater gives operators the ability to decide exactly how much lubricant needs to be applied through five simple entries in the FinCoater controller. These settings can be changed in seconds and the adjustment is instant.

FinCoater is mounted in the existing lubricant bath; no more lubricant spilling on the floor or on operators. No more aluminum smut buildup in the lubricant bath.

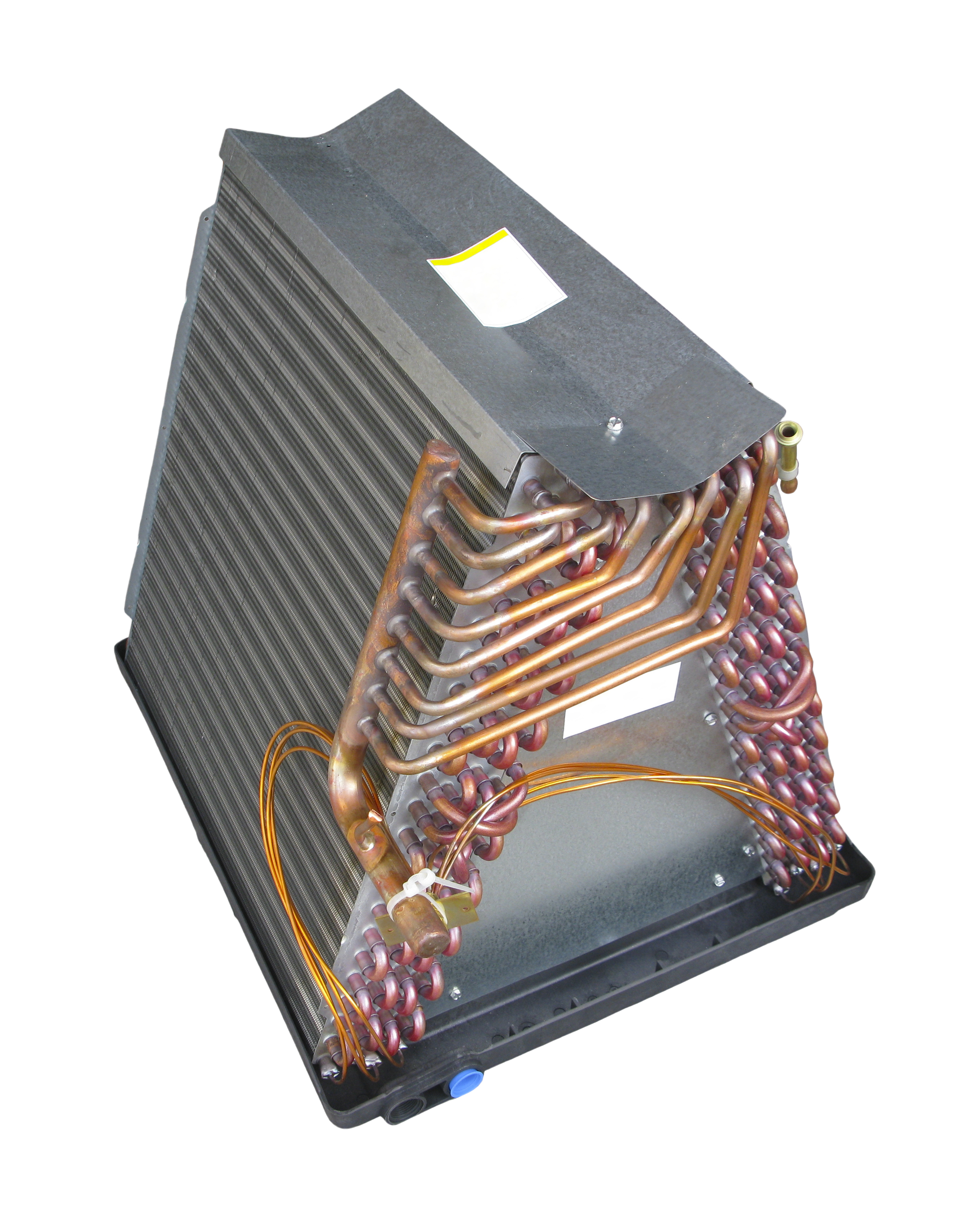

FinCoater has a 4, 8 or 15 gallon reservoir available that is mounted to the side of the press area. Lubricant is pumped to the felt rollers and the specified lubricant amount activated by the controller is applied to the felt rollers then applied to the aluminum surface. The FinCoater has two sets of rollers: The first set is to stabilize the aluminum as the second set of rollers applies the specified amount of lubricant. This control eliminates over application that causes safety concerns like operators clothing and gloves soaked with lubricant. It also reduces evaporator or condenser coils having excess lubricant which can lead to residue issues such as soaking packaging or shipping dunnage.

Chem Arrow offers an assessment to specify what size FinCoater is needed, provides a quote with a return on investment estimate and a 30-day trial for a unit to justify performance and return on investment.

Benefits of the Chem Arrow FinCoater:

- Reduces lubricant usage up to 50% providing a quick return on investment.

- Provides the ability for specific amount of lubricant to be applied.

- Adjustments are instantaneous.

- Easily programable allowing for part numbers assigned to specific fins per inch that need more lubricity. Simply pick the part number and changes are done.

- Eliminates lubricant bath, aluminum smut buildup and no lubricant splashing on the floor.

- Greatly reduces or eliminates operator’s exposure to soaking of gloves or clothing and lacing table lubricant buildup.

- Reduces lubricant application dramatically.

- Reduces HVAC coils total lubricant residue which minimizes or eliminates over application residues such as smoke during coil brazing, smoke/odor issues on heating coil units, soaking of shipping packaging or dunnage and lubrication cleanliness safety concerns.

Please contact us at hvac@chemarrow.com for your free FinCoater assessment.

Download Fin Coater Brochure