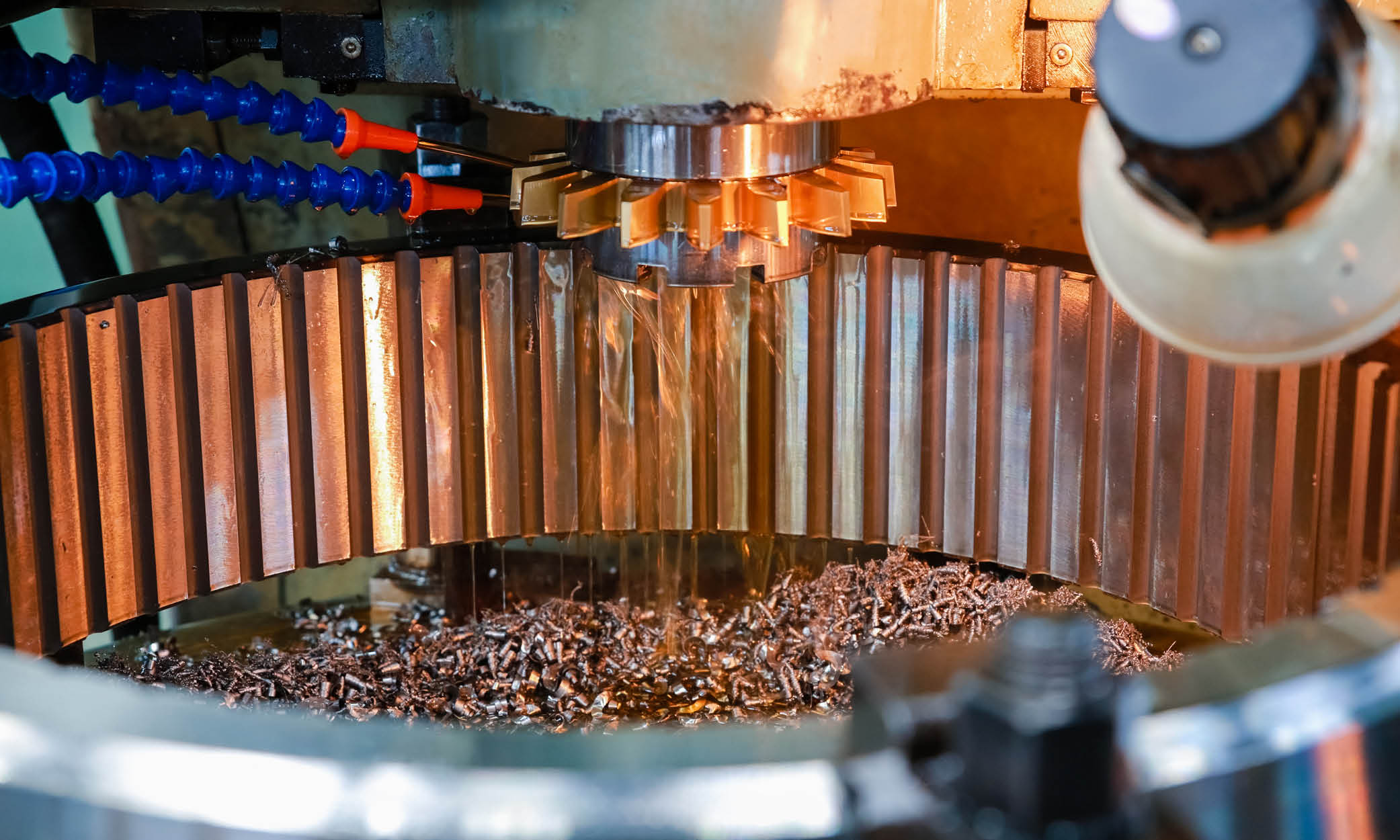

The modern CNC machine tool is a substantial investment. Protecting it from corrosion is critical.

Rust is a reaction of both iron and oxygen in the presence of moisture. The combination of these elements can create corrosion on tool holders, fixtures and machine beds and ways. Corrosion can impact the performance and shorten the life cycle of your machine. Most metalworking fluids provide some in-process corrosion protection, but it is often not enough to provide long term rust protection for your equipment.

Here are some tips for reducing corrosion on your equipment:

- Manage your metalworking fluids.

- Concentration control is critical. Maintain the recommended concentration for your fluid and application.

- Mix the fluid properly with an automated mixer or mix manually. Ensure the metalworking fluid is added to the water, not the other way round, to avoid an inverted emulsion (Remember: OIL - Oil In Last).

- Remove tramp oil from the surface of the machine tool to reduce bacteria, a contributing factor to corrosion.

- Use the best quality water you can. Eliminating hard water improves fluid quality and the stability of your fluid.

- Do annual machine cleaning and preventive maintenance to eliminate residue and chip build-up.

- Machine tools need to be properly grounded to eliminate free electric flow.

- Keep machine tool doors open at night to minimize condensation build-up in the interior of the machine tool.

- Ensure you have a source of dry shop air to clean fixtures and tools.

- Avoid fixturing dissimilar metals. This can often lead to galvanic corrosion on your fixtures and vises.

- Use a light oil rust preventative on key areas of your machine tool to prevent corrosion.

ArrowRP 12991 is a great option.

Corrosion issues are often one of the most difficult and costly issues in a facility. Proactively monitoring your fluid and the environment around the machine tool will help minimize the risk of corrosion. Working with your maintenance department, along with your fluid supplier and machine tool supplier, will also help reduce the problem of corrosion on your equipment.